Product

● 1023 BRT, 1011 BRT, 1021 BRT, 1027 BRT, 1031 BRT ● Nylon-6/ Nylon-66 copolymer material under development ● Completed material approval from global compound manufacture ● Application: Automotive parts, electrical and electronic parts

● 1023 BRT, 1011 BRT, 1021 BRT, 1027 BRT, 1031 BRT ● Nylon-6/ Nylon-66 copolymer material under development ● Completed material approval from global compound manufacture ● Application: Automotive parts, electrical and electronic parts

| Product | Relative Viscosity |

Moisture Content |

Monomer Content |

Yellow Index |

Melting Point |

MI (2.16kg) |

Chip Shape | Chip Size |

|---|---|---|---|---|---|---|---|---|

| Unit | - | % | % | - | ℃ | g/10min | g/100ea | |

| 1023 BRT | 2.30±0.03 | 0.05±0.02 | Max 0.70 | Below 2.0 | 220 | 107 | Pillow | 0.8 |

| 1011 BRT | 2.45±0.03 | 0.05±0.02 | Max 0.70 | Below 2.0 | 220 | 60 | Pillow | 0.8 |

| 1027 BRT | 2.70±0.03 | 0.05±0.02 | Max 0.70 | Below 2.0 | 220 | 38 | Pillow | 1.0 |

| 1021 BRT | 2.97±0.03 | 0.06±0.02 | Max 0.70 | Below 2.0 | 220 | 20 | Pillow | 0.8 |

| 1031 BRT | 3.48±0.03 | 0.06±0.02 | Max 0.90 | Below 2.0 | 220 | 9 | Pillow | 0.95 |

| Method | ISO 307 | ISO 15512 | ISO 6427 | ASTM E313 | ISO 3146 | 250℃ |

*1027CS: Injection molding grade with excellent release properties and crystallinity characteristics

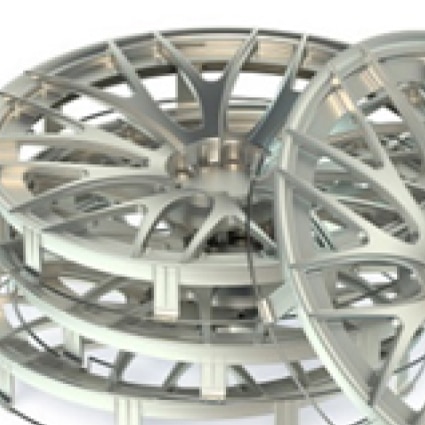

● Excellent quality ● Excellent dimensional ● Excellent resilience ● Excellent mechanical properties realized with glass fiber reinforcement

| ITEM | Unit | Method | 1027 BRT + Glass fiber 30% | |

|---|---|---|---|---|

| DRY | COND. (50% RH) | |||

| Tensile Strength | MPa | ASTM D-638 | 180 | 150 |

| Tensile Modulus | MPa | ASTM D-638 | 10,000 | 7,800 |

| Elongation at Break | % | ASTM D-638 | 3.5 | 5 |

| Flexual Strength | MPa | ASTM D-790 | 220 | 220 |

| Flexual Modulus | MPa | ASTM D-790 | 8,700 | 6,700 |

| Impact Strength (Izod, Notched) |

KJ/m2 | ASTM D-256 | 15 | 19 |

| Thermal Deflection temperature (1.82MPa) |

℃ | ASTM D-648 | 210 | - |

| Specific Gravity | - | ASTM D-792 | 1.36 | - |

| Items | Unit | Method | 1011 | 1027 | 1021 | 1031 | Remark |

|---|---|---|---|---|---|---|---|

| Tensile Strength | MPa | ASTM D-638 | 73 | 74 | 75 | 75 | 50mm/min,115mm |

| Tensile Modulus | MPa | ASTM D-638 | 2,600 | 2,600 | 2,650 | 2,650 | |

| Elongation at Break | % | ASTM D-638 | 140 | 140 | 140 | 140 | |

| Flexual Strength | MPa | ASTM D-790 | 98 | 99 | 101 | 103 | 1.3mm/min, 51mm |

| Flexual Modulus | MPa | ASTM D-790 | 2,400 | 2,500 | 2,600 | 2,700 | |

| Impact strength (Izod, Notched) |

KJ/m2 | ASTM D-256 | 6 | 6 | 7 | 7 | At 23℃, 2.54mm(notch) |

| Thermal Deflection Temperature |

℃ | ASTM D-648 | 65 | 65 | 65 | 65 | 2℃/min, 1.82MPa |

| Vicat softening temperature |

℃ | ASTM D-1525 | 195 | 195 | 195 | 195 | 2℃/min,50N |

| Rockwell Hardness | R-scale | ASTM D-785 | 120 | 120 | 120 | 120 | |

| Coeff. of Linear Thermal Expansion |

Cm/cm. ℃ | ASTM D-696 | 0.8 | 0.8 | 0.8 | 0.8 | |

| Thermal Conductivity |

W/m. °F | ASTM D-177 | 1.7 | 1.7 | 1.7 | 1.7 | |

| Dielectric Strength | KV/mm | ASTM D-149 | 19 | 19 | 19 | 19 | |

| Specific Gravity | - | ASTM D-792 | 1.14 | 1.14 | 1.14 | 1.14 | |

| Mold Shrinkage | /t(1/8”) | % | ASTM D-955 | 1.0 ~ 1.6 | 1.0 ~ 1.6 | 1.0 ~ 1.6 | 1.0 ~ 1.6 |

| Moisture Absorption | % | ASTM D-570 | 1.5 | 1.5 | 1.5 | 1.5 | At 23℃, 24hrs, water |

| Relative Viscosity | - | ISO 307 | 2.45 | 2.7 | 2.97 | 3.48 | |

| Melt Flow Index | g/10min | ASTM D-1238 | 60 | 38 | 20 | 9 | 2.16kg, 250℃ |

*Water Absorption condition: 23℃, Equilibrium 50%RH